- You have no items in your shopping cart

- Subtotal: 0,00 د.إ

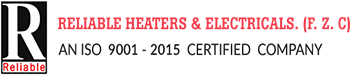

Tubular Heating Element

Heating Element

Applications of Tubular Heaters

- Paint and Enamel Baking Equipment

- Silo Heaters and Hopper – Food, Agriculture, and Plastic

- Animal Incubators for Prenatal Care

- Food Service Equipment

- Ducts

- Epoxy Curing

- Furnaces

- Fusing Laminated Sheets

- Kettles and Tanks

- Ovens – Process, Curing, Food

- Stretch Wrapping Equipment

- Plastic Sheet Bending Equipment

- Spas and Hot Tubs

- Steam Tables

- Welding Preheat Equipment

- Sterilizers and Autoclaves

- Textile and Chemical Dryers

Advantages of Tubular Heaters

Precision

One of the key benefits of tubular heating components is precision. They enable precise heat transfer, improved temperature maintenance, and enhanced temperature management. Temperatures up to 750°C (1,382°F) and watt densities up to 120 WPSI are possible. Moreover, they are adaptable enough to fit almost any application. Additionally manufactured to order, the cold sections shield the terminals. As a result, tubular heating elements can function more effectively and last longer with extreme precision. They are, therefore, affordable and effective.

Compact Size

Tubular heating components’ small size has a lot of benefits. Installing them is simply because of their smaller and customized sizes. They are simple to maintain, repair, or replace because they are small. Since these components are simple to take out and put back in, the production process can continue for a short time.

Customization

Tubular heating elements come in various sizes and shapes and are made for maximum durability. The components are set up in the factory to be the ideal size and shape for a given application. Higher performance is possible by bending diameters and radii to fit an application’s form, fit, and functions. Tubular heaters are cheaper than coolers of the plate kind.

- Tubular heaters can be applied to systems that operate at higher operating pressures and temperatures.

- Due to the relatively simple nature of pressure testing, tube leaks are more easily found and repaired.

- In a refrigeration system, tubular coolers can also function as a receiver.

- Sacrificial anodes prevent corrosion throughout the entire cooling system.

- Due to the pressure differential, tube coolers may be preferred for lubricating oil.

| Part no | Made-to-order |

| Ratings | Made-to-order |

| Dimensions | Made-to-order |

| Brand | RHE |

Tubular heaters are frequently submerged in water, oil, or molten metals. Tubular heaters are very energy-efficient because they produce heat inside a liquid or process. Since they may be made of practically any size or shape, tubular heaters are utilized in many industries and process heating applications. Tubular heaters can be used in any area requiring quick, dependable, and affordable heating.

Reliable Heaters & Electricals FZC manufactures a wide range of tubular heating and immersion heating elements for the domestic & commercial industry which are used in a vast range of appliances and machines such as:

Bain maries – wet or dry electrical heaters

Commercial deep fryer electric heating

Pizza & Bakery electric heating ovens

Tandoor electric heating ovens

Commercial toaster electric heating elements

Griller electric heating elements

Dishwashers electric heating elements

BBQ electric heating elements

Electric heating of Plate ovens and warmers

Electric heating of Hot food bar displays, hot boxes

food warmer electric heating elements

Salamanders electric heating elements.

Additional Information

| Part No | Made-to-order |

|---|---|

| Ratings | Made-to-order |

| Dimension | Made-to-order |