- You have no items in your shopping cart

- Subtotal: 0,00 د.إ

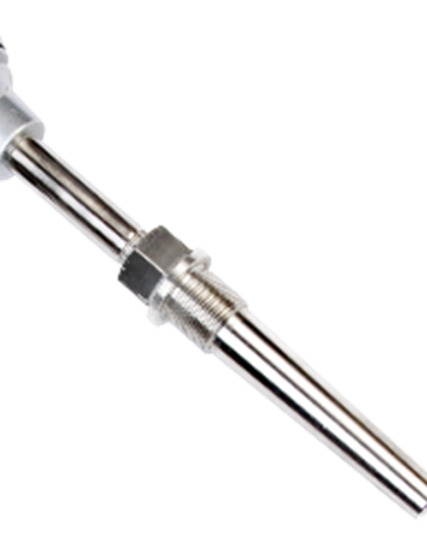

Thermocouple

Types of Thermocouples

All thermocouple assemblies can be divided into groups of noble metal thermocouples and base metal thermocouples, each having distinct characteristics suitable for specific applications. Some applications of thermocouples are as follows.

Noble metal thermocouples are those thermocouples made from noble, or precious, metals, which are metals with high resistance to corrosion from chemicals and organic acids. Also, noble metal thermocouples all measure up to 2000°C. Noble metal thermocouples include types: K, N, R and S.

Base metal thermocouples may be composed of any metal except a noble metal. Base metal thermocouples include types: T and J.

In addition to these thermocouple groupings, there are many others, defined in various ways, such as by sensitivity levels. Type B thermocouples, for example, are known for their low sensitivity.

Type K Thermocouple

The most universal thermocouple type is the Type K thermocouple, which consists of two alloy wires, alumel (aluminum and nickel) and chromel (chromium and nickel). Type K’s have a high temperature resistance to be used with everyday devices.

Type J Thermocouple

These base metal thermocouples are usually made from a pairing of iron and constantan. They may also feature stainless steel, a durable iron alloy. Like Type T thermocouples, they are best for use with low temperature applications. They can also, however, be used for brief high temperature applications.

RTD Sensor

For higher temperatures, RTDs are a much better choice; they accurately (within +0.5%) measure temperatures between -200℃ and 800℃. While RTDs tend to have produce tighter accuracies than thermocouple assemblies, thermocouples have a much higher heat capacity and are much less expensive to make and use. Thermocouple and RTD assemblies are both valuable, but thermocouples are the most popular temperature measurement system because they are simply constructed, easily installed and inexpensive. In addition, they boast short response times, good readability, wide temperature ranges and more application options than thermistors and RTDs.

Industries that Use Thermocouples

Food and Beverage

Thermocouples are widely used in food and beverage manufacturing facilities to provide accurate and precise temperature readings necessary in heating, cooling, frying, or cooking processes. They can be found in ovens, warmers, fryers, toasters, grills, freezers, and more. It should be noted that these industries require a high level of cleanliness and a sanitary design for temperature sensors must be used.

Power Generation

Type J, K, and N thermocouples are commonly used in power plants due to their wide temperature range and ability to perform in extreme environments. Thermocouples are needed in power plants for accurate monitoring and control of the flow of energy.

Automotive and Aerospace

Thermocouples play an important role in managing vehicle diagnostics, improving engine performance, and increasing vehicle safety. Temperature readings by engine thermocouples and other sensors are essential to monitoring exhaust gas readings, cylinder heads, spark plugs, and car batteries.

Metal Processing

Factories producing aluminum, iron, steel, and other metals use thermocouples to track temperature during production. Metal processing plants use very high temperatures to melt metals. Types K, N, R, S, and B are the thermocouple types capable of withstanding these extreme conditions.

Thermocouples are simple, inexpensive sensors with a wide temperature range. They are self-powered and do not need external excitation to function. Many applications utilize them because of their reproducibility, rugged construction, accuracy, and high speed of response.

| Part no | Made-to-order |

| Ratings | Made-to-order |

| Dimensions | Made-to-order |

| Brand | RHE |

Thermocouple also called, temperature sensors or temperature probes, are instruments that both sense heat and control temperature. Consisting of two connected, dissimilar metal wires. their operation is based on the Seebeck Effect, which theorizes that a voltage is always created between two dissimilar metals, and that said voltage changes in proportion to exterior temperature changes.

Thermocouple Applications

Thermocouple Sensor are used for industrial, residential and commercial purposes alike. Systems and devices that use them include: water tanks, plastic extrusion machines, heat exchangers, general heating equipment, parts washers, kilns, ovens, water heaters, furnaces, pressure chambers and thermostats.

Types of Thermocouples

All thermocouple assemblies can be divided into groups of noble metal thermocouples and base metal thermocouples, each having distinct characteristics suitable for specific applications. Some applications of thermocouples are as follows.

Noble metal thermocouples are those thermocouples made from noble, or precious, metals, which are metals with high resistance to corrosion from chemicals and organic acids. Also, noble metal thermocouples all measure up to 2000°C. Noble metal thermocouples include types: K, N, R and S.

Base metal thermocouples may be composed of any metal except a noble metal. Base metal thermocouples include types: T and J.

In addition to these thermocouple groupings, there are many others, defined in various ways, such as by sensitivity levels. Type B thermocouples, for example, are known for their low sensitivity.

Type K Thermocouple

The most universal thermocouple type is the Type K thermocouple, which consists of two alloy wires, alumel (aluminum and nickel) and chromel (chromium and nickel). Type K’s have a high temperature resistance to be used with everyday devices.

Type S Thermocouple

Type S thermocouples are made from a pairing of platinum and 10% rhodium. They are known for their high accuracy, high stability and ability to work well in high temperature applications. Most often, they’re used in pharmaceutical and biotech applications, though they can also be used with low and mid-level temperature applications.

Type T Thermocouple

Type T thermocouples are base metal thermocouples that are usually made from a combination of copper and constantan. They can measure temperatures under 1000°C and are therefore common for use in cryogenics or ultra-low temperature freezers. Commonly, they’re composed of tin, nickel, copper, aluminum or lead. They measure

Type J Thermocouple

These base metal thermocouples are usually made from a pairing of iron and constantan. They may also feature stainless steel, a durable iron alloy. Like Type T thermocouples, they are best for use with low temperature applications. They can also, however, be used for brief high temperature applications.

Type C Thermocouple

Type C refractory metal thermocouples are named after refractory metals, which are coated in material with a high melting pointing. Handling temperatures above 2600°C, they have the highest heat resistance.

Type E Thermocouple

Type E thermocouples are composed from paired Nickel-Constantan and Nickel-Chromium. It is used with applications that require extra high accuracy.

Alternatives to thermocouples include thermistors and resistance temperature detectors (RTDs). Both of these devices use the electrical resistance of certain metals to measure temperature change.

Thermistor

Thermistors are made from metal oxides, which have an inverse resistance to rising temperature; as temperatures increase, thermistor resistance falls. For this reason, thermistors fall into the category of “negative temperature coefficient” (NTC) sensors. As they only accurately measure environments up to 200℃, thermistors are only appropriate for low to mid-temperature applications.

RTD Sensor

For higher temperatures, RTDs are a much better choice; they accurately (within +0.5%) measure temperatures between -200℃ and 800℃. While RTDs tend to have produce tighter accuracies than thermocouple assemblies, thermocouples have a much higher heat capacity and are much less expensive to make and use. Thermocouple and RTD assemblies are both valuable, but thermocouples are the most popular temperature measurement system because they are simply constructed, easily installed and inexpensive. In addition, they boast short response times, good readability, wide temperature ranges and more application options than thermistors and RTDs.

Industries that Use Thermocouples

Food and Beverage

Thermocouples are widely used in food and beverage manufacturing facilities to provide accurate and precise temperature readings necessary in heating, cooling, frying, or cooking processes. They can be found in ovens, warmers, fryers, toasters, grills, freezers, and more. It should be noted that these industries require a high level of cleanliness and a sanitary design for temperature sensors must be used.

Power Generation

Type J, K, and N thermocouples are commonly used in power plants due to their wide temperature range and ability to perform in extreme environments. Thermocouples are needed in power plants for accurate monitoring and control of the flow of energy.

Automotive and Aerospace

Thermocouples play an important role in managing vehicle diagnostics, improving engine performance, and increasing vehicle safety. Temperature readings by engine thermocouples and other sensors are essential to monitoring exhaust gas readings, cylinder heads, spark plugs, and car batteries.

Metal Processing

Factories producing aluminum, iron, steel, and other metals use thermocouples to track temperature during production. Metal processing plants use very high temperatures to melt metals. Types K, N, R, S, and B are the thermocouple types capable of withstanding these extreme conditions.

Thermocouples are simple, inexpensive sensors with a wide temperature range. They are self-powered and do not need external excitation to function. Many applications utilize them because of their reproducibility, rugged construction, accuracy, and high speed of response.

Additional Information

| Part No | Made-to-order |

|---|---|

| Ratings | Made-to-order |

| Dimension | Made-to-order |