- You have no items in your shopping cart

- Subtotal: 0,00 د.إ

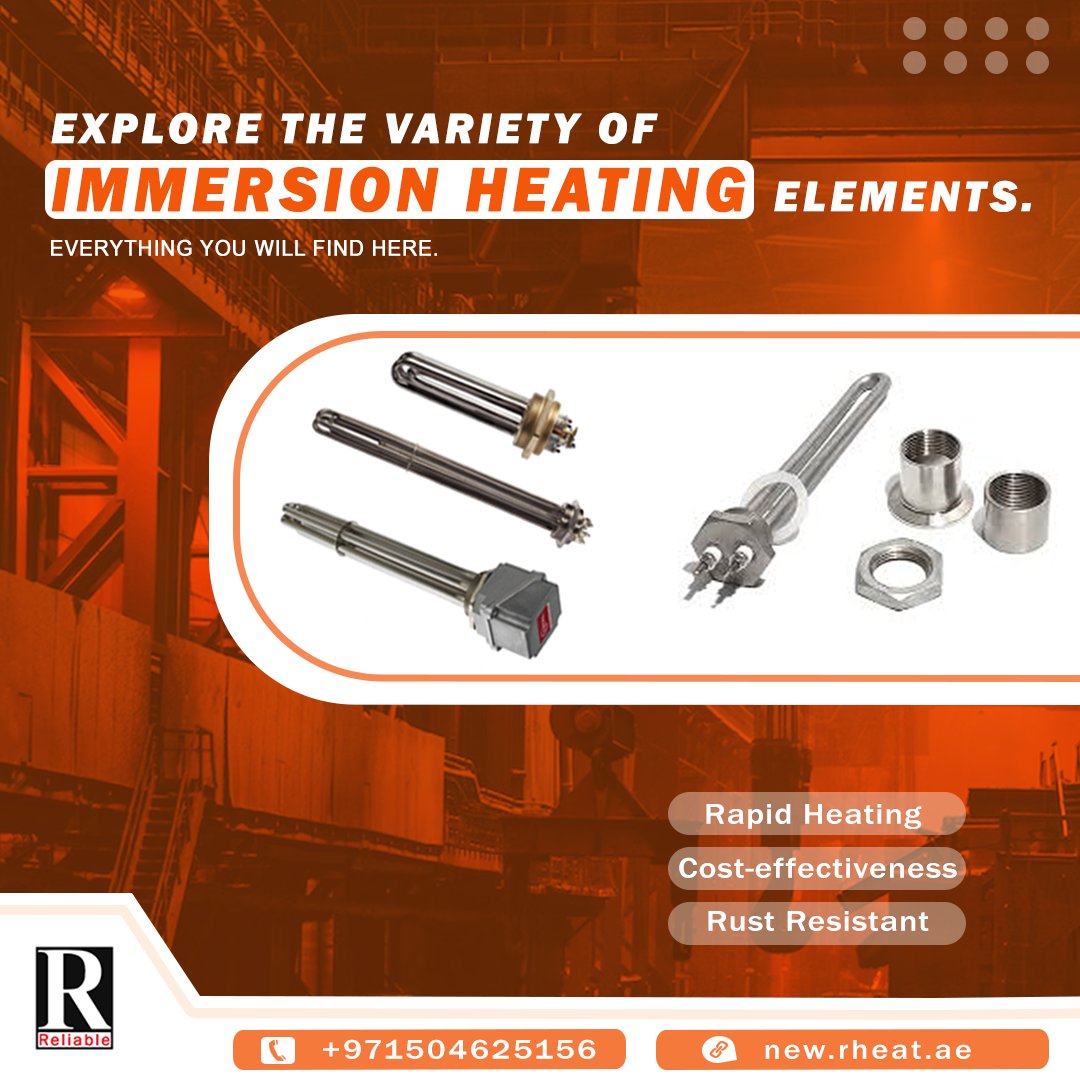

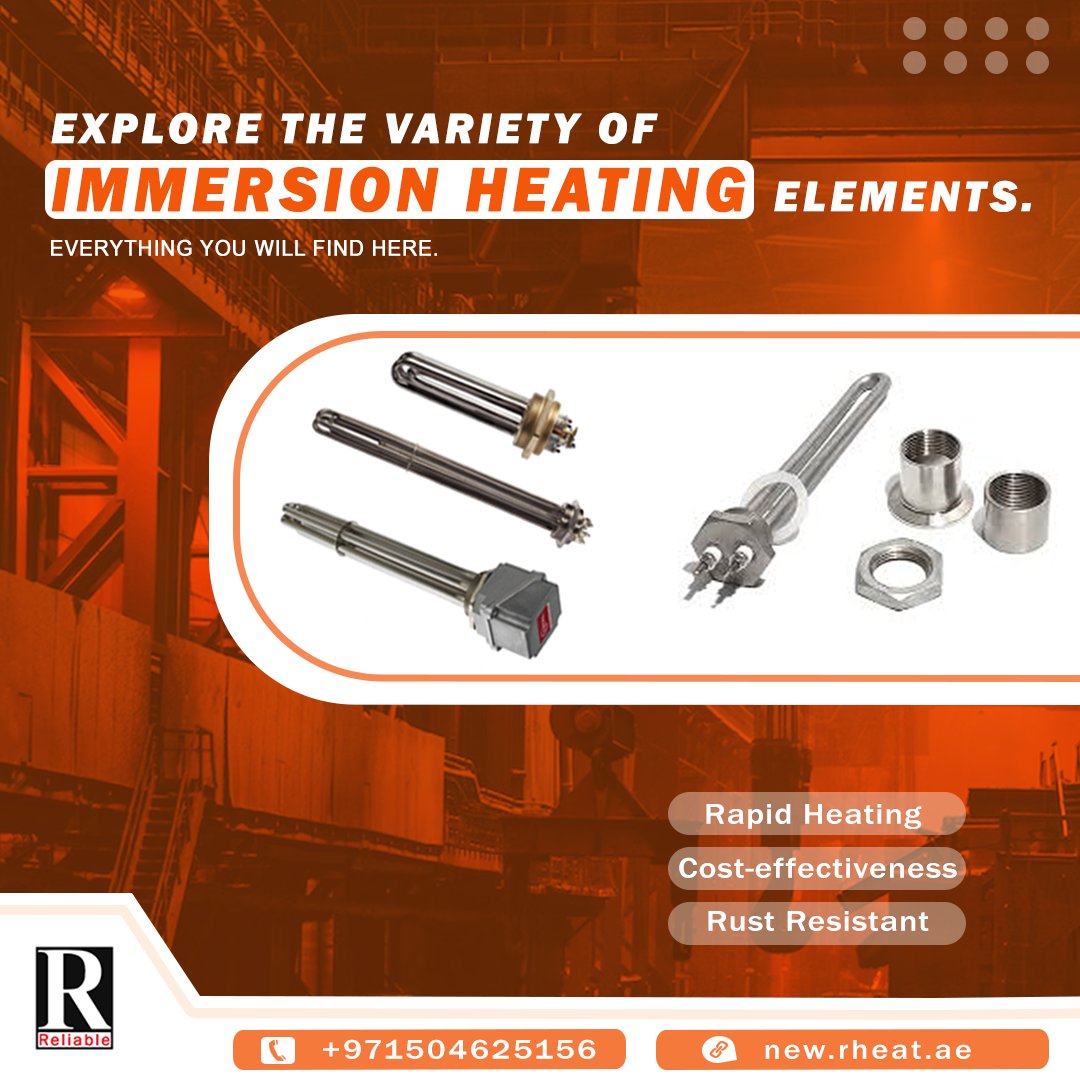

In industries, keeping things at the right temperature is super important. That’s where immersion heaters come in. They’re like superheroes of heat, helping with various jobs. Electric immersion heaters are heating elements in the form of tubular elements that are used to directly heat liquids in a range of industries, including power, chemical, oil and gas, pharmaceuticals, food and beverage, and metals processing. These heaters, often called bayonet heaters, have heating components that you can put straight into a water or oil container to heat the contents completely.

What are Immersion Heaters?

Imagine a device that goes right into a liquid or gas to heat it up – that’s an immersion heater. It has a heating part inside a protective cover, usually made of tough materials like stainless steel.

How Do They Work?

These heaters use electricity to create heat. The electric current goes through the heating part, which then warms up and passes the heat to whatever it’s in – like water or oil.

Key Components:

- Heating Element: The core of the heater, responsible for generating heat.

- Sheath Material: Protects the heating element from corrosion and chemical reactions with the substance being heated.

- Thermostat: Controls the temperature, ensuring it stays within the desired range.

- Control Panel: Manages the overall operation of the immersion heater, allowing for adjustments and monitoring.

Applications Across Industries:

- Oil and Gas: Immersion heaters are used to maintain the viscosity of oils and prevent them from solidifying in pipelines.

- Chemical Processing: They play a crucial role in heating and maintaining the temperature of various chemicals during production processes.

- Water Treatment: Immersion heaters are employed to heat water for industrial processes like cleaning and sanitation.

- Food and Beverage: In the food industry, which are used for tasks such as melting chocolate or heating liquids in large-scale cooking processes.

- Plastics Industry: which are utilized in molding processes to achieve specific temperatures for shaping plastic materials.

Benefits of Industrial Immersion Heaters:

- Precision: which offer precise temperature control, ensuring that processes are carried out with accuracy.

- Efficiency: Direct immersion allows for efficient heat transfer, minimizing energy loss.

- Versatility: With various sheath materials available, immersion heaters can be customized to suit the specific requirements of different industries and substances.

Conclusion:

Even though it is work quietly, they’re crucial in industries as well as tubular heaters. From making sure chemicals react the way they should to keeping food quality high, these heaters do a lot. As industries grow, immersion heaters will continue to be a big help in keeping things running smoothly. When it comes to Immersion Heater in Dubai, RELIABLE HEATERS & ELECTRICALS provide heating elements that will make your industrial heating needs more useful and longer lasting. Contact us for more information.